The number 1 question I get asked when people email me is “How to verify a supplier in China” – without actually going there or hiring a third party to do an audit at the factory?

And it’s a very good question at that. It isn’t easy to verify a supplier 100% over the phone or via email. However there are several approaches that I take before I decide to place an order with a supplier.

I like to divide this into three parts:

1) “Developing a feeling”

2) Background research you can do for free

3) Background research you can pay for

1) “DEVELOPING A FEELING”

It all starts with communication. When I reach out to a supplier I keep a professional approach. Meaning I explain who I am, what I do, even attach my company presentation to my initial inquiry. If you don’t have a presentation don’t worry, it’s not necessary. But you should explain in your email with a few sentences what you do and who you are. This gives the supplier an image of you and won’t make him think that you are just some random person who has no idea about importing from China.

I also look for suppliers who respond to all my questions in detail. Ever emailed a supplier with lots of questions and all you get was partial answers and cryptic replies? You are not alone. I immediately eliminate these suppliers in my selection.

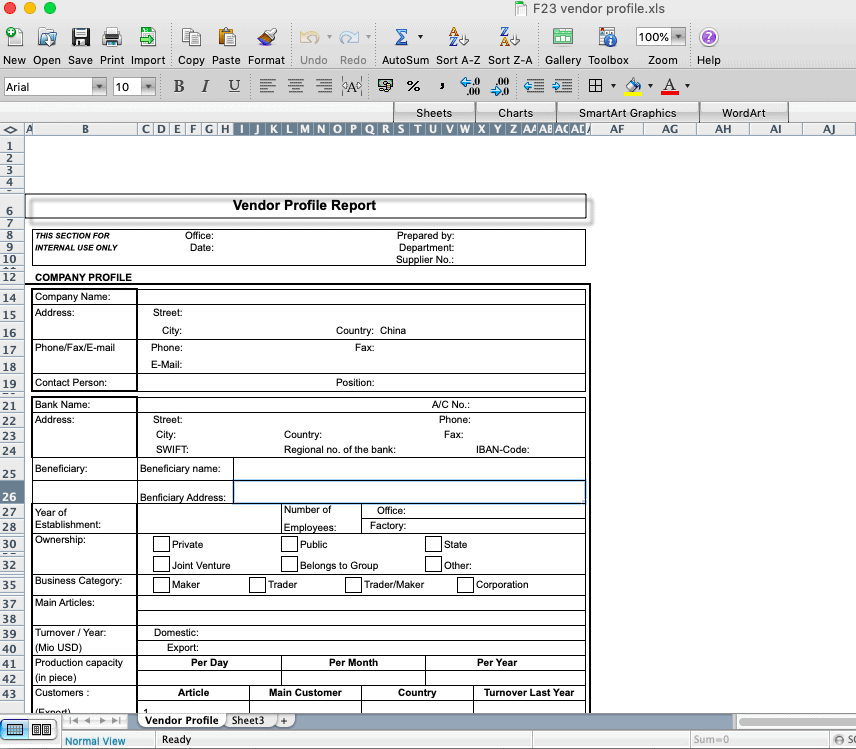

If he can’t reply to a few questions in my initial outreach imagine how it will be like down the road. You usually filter from 10 suppliers down to 3. Once I have these 3 suppliers that have somewhat answered all my questions and are reasonably priced I start digging into their background. For this I use a “vendor profile report” that I created. It looks like this:

In this report I collect a lot of information from the supplier such as:

– Contact name, telephone number, email address, fax number etc.

– Bank name, beneficiary etc. – I use this information to make sure the bank account name matches the company name. Often times suppliers have a bank account in Hong Kong due to its ease of financial transactions. For example if the suppliers name is: Shenzhen Toys Import and Export it should match the bank acount name. If a supplier uses a Hong Kong bank account it often differs slightly. It could be: Shenzhen Toys Import & Export Hong Kong Limited. This would be ok; however if I receive a name that is completely different than the original supplier name I will ask questions. This could be a first red flag!

– Year of establishment, turnover, production capacity. This gives me an indication if the supplier has some experience in his industry. E.g. it’s a good sign if I look for a vacuum cleaner and the supplier has 20 years of experience. I may not want to go with a supplier who has only been established 1 year ago. I will want a supplier who has had at least some years of experience in the certain product industry.

– Customers, main markets. This will tell me if my supplier has experience working in key markets like the US or Europe. If his main customers or markets are in Arabia, South America or Russia for example he may not be the right supplier for me. Reason being that these countries have totally different quality requirements than the US or Germany for example. I will want a supplier who at least has had some experience in my markets. Makes it easier for me to explain my quality and other standards.

– Does he exhibit at trade shows like the Cantonfair or in Hong Kong? This gives me an indication if he had exposure to international customers and if he is actively looking to branch out into other markets. The more exposure a supplier has to international buyers the better.

– Factory address, quality management system at the factory, how many workers, in house R&D etc. – This gives me an idea of the capacity and general standard of the factory. Has the factory been audited by a third party before? Can the supplier send me this audit report? These things will tell you how well a factory is equipped with machinery and if they are actively improving their standards.

Once I collected above information I can get a pretty good feeling with who I am dealing with. If a supplier isn’t willing to share this information with you he either has something to hide or he isn’t really interested in cooperating or working with you.

If you feel this is all a little too much just to find a supplier, think twice. This is someone who you’ll send money to and hopefully be your partner for many years. A supplier who understands this and cooperate with you sending you all this information should be the supplier you choose.

Pricing really is just a secondary decision maker for me. Say I have narrowed down to 3 suppliers but I am having difficulties communicating with 2 of them. Even tough the 3rd supplier may be more expensive than the others, if he is the one whom I communicate best with I will go for the more expensive supplier.

Consider also, if you have any problems with your product on Amazon you’ll want a supplier who can help you with refunds or replacing defect items. If you went with a supplier that was just cheap and not really willing to work with you in the first place you’ll have a hard time getting any money or replacements down the road. It’s also wise not to squeeze every cent out of a supplier. If he can’t properly pay his staff and workers what good does that for me when he won’t be around anymore next year. Live and let live.

2) BACKGROUND RESEARCH YOU CAN DO FOR FREE

Apart from the above, as a next step before placing an order I will ask the supplier to provide me with the certificates that he claimed to have. For example if he claimed to have a CE or FDA certificate for a specific product I will want to see a soft copy (PDF).

Sometimes suppliers won’t be able to send you a full test report/certificate because it was applied and paid for by their customers. Fair enough, but he can blur out some information and send you a screenshot.

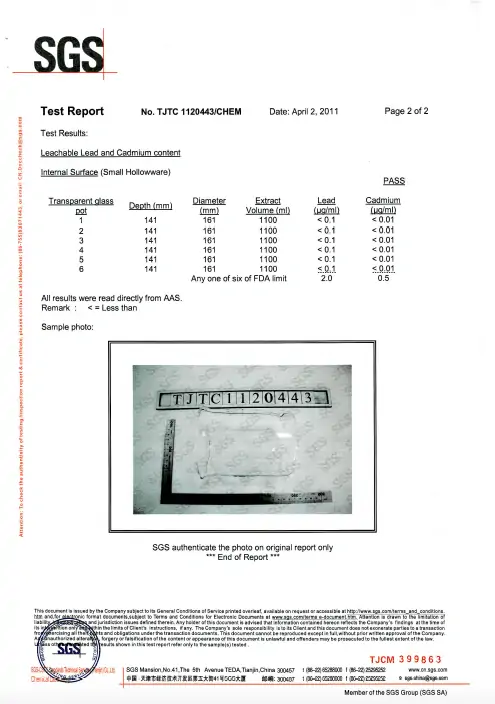

But in many cases the test reports/certificate are in the name of the supplier. Once you’ll receive these soft copies you can then contact the issuing third party. Let’s take a look at below example:

As you can see above this was a FDA report for one of my items. Once I receive the report I can contact the issuing third party (SGS in this case), quote them the test report number and ask for its validity. You’ll also find contact details on most test reports.

[thrive_leads id=’51377′]

Normally a third party will do this for free (confirming a validity). Once they’ve confirmed the validity I can somewhat safely move forward with the supplier. However, many suppliers fake their certificates and test reports and it’s not uncommon that once you contact the (supposed) third party that they never heard from this test report. Steer clear and eliminate this supplier immediately.

This also goes for factory audit reports. Again, often times audits are done by other customers and suppliers can’t send you the full report. However a screenshot with blurred out areas will do. If they can send you a full report look for details such as:

- when was the factory audited?

- what were the findings or main issues?

- did the supplier improve these issues since then?

- where there any major critical findings? (such as child labour)

Once you’ve concluded your research of the audit report you should have a pretty good picture of the supplier. Then it really is up to you to move forward with all your findings, place an order or go to the last and final step:

3) BACKGROUND RESEARCH YOU CAN PAY FOR

As a final step if you are still not 100% convinced you can perform a third party audit at a factory. There are many providers who will go to the factory and perform a standard audit.

These audits are a paid service. During these audits the third party will conduct a thorough research of the factory based on criteria that you can help determine.

For example once you’ve booked an audit you can tell the third party that you plan on selling in the US and the factory would need to be up to those standards. The third party will also perform a standard audit based on their experience.

Costs are usually from 500$ upwards for an audit. That includes travelling to the factory, one full day of auditing and sending you a report. I always use QIMA.COM (formerly known as Asiainspection) and they charge 649$. There are cheaper services of course. I suggest to do your own research. Bigger companies like TUV or SGS usually charge 800$ upwards.

So whether you want to do an audit is really up to you. Often times I’ve developed a pretty good with feeling on a supplier with 1) & 2). It does make sense to perform 3) if you have no other suppliers and want to make 100% sure everything’s ok.

After I’ve gone trough all of the above I should get a really good feeling about the supplier. Sometimes I look more than 2 months for a supplier if I feel the ones I found aren’t right for the job.

It really is not a sprint, its a marathon on finding and building a relationship with a supplier.

Paid services are obviously one of the most fool proof ways however they cost quite some money and if you were to pay for each audit at every factory you want to start working with it will surely cost a lot of money in the long run.

Bear in mind that larger companies (such as the one I used to work for) usually has an office in Asia and they send a team of their own people to investigate every factory before they place an order there. But if you don’t have your own team in Asia you may want to hire the following:

Third Party Audit (SGS, QIMA, TUV, INTERTEK etc.)

It’s also important to note that I am willing to work with more in-experienced and “new to the market” suppliers. Reason being that these may not have the experience but they are willing to accept smaller order quantities or work with smaller customers.

You can then grow with these suppliers. Imagine you grew a supplier along the way. He’ll always be grateful and he’ll be supportive and helping whenever you need him.

I have two of these suppliers among my portfolio. We share a lot of information from the market, I get the best prices out of all his customers, the newest items are always reserved for me, they’d help if I have a lot of returns and on top of all I have payment terms that allow me to keep a great cash flow (usually I pay 90 days after the products have been shipped).

So you see, building a relationship with a supplier is very important and can benefit you in so many ways. Yes, sometimes I see suppliers who may offer cheaper prices but it simply isn’t worth it to switch a supplier just because I save 0.2$ on the product cost. I’d also have to explain the whole workflow to this new supplier. Me and my suppliers are practically a well-oiled-team which helps me immensely.

So I guess I recommend taking your time when selecting a supplier. Don’t rush things and filter properly.